RES in Scotland

Case Studies

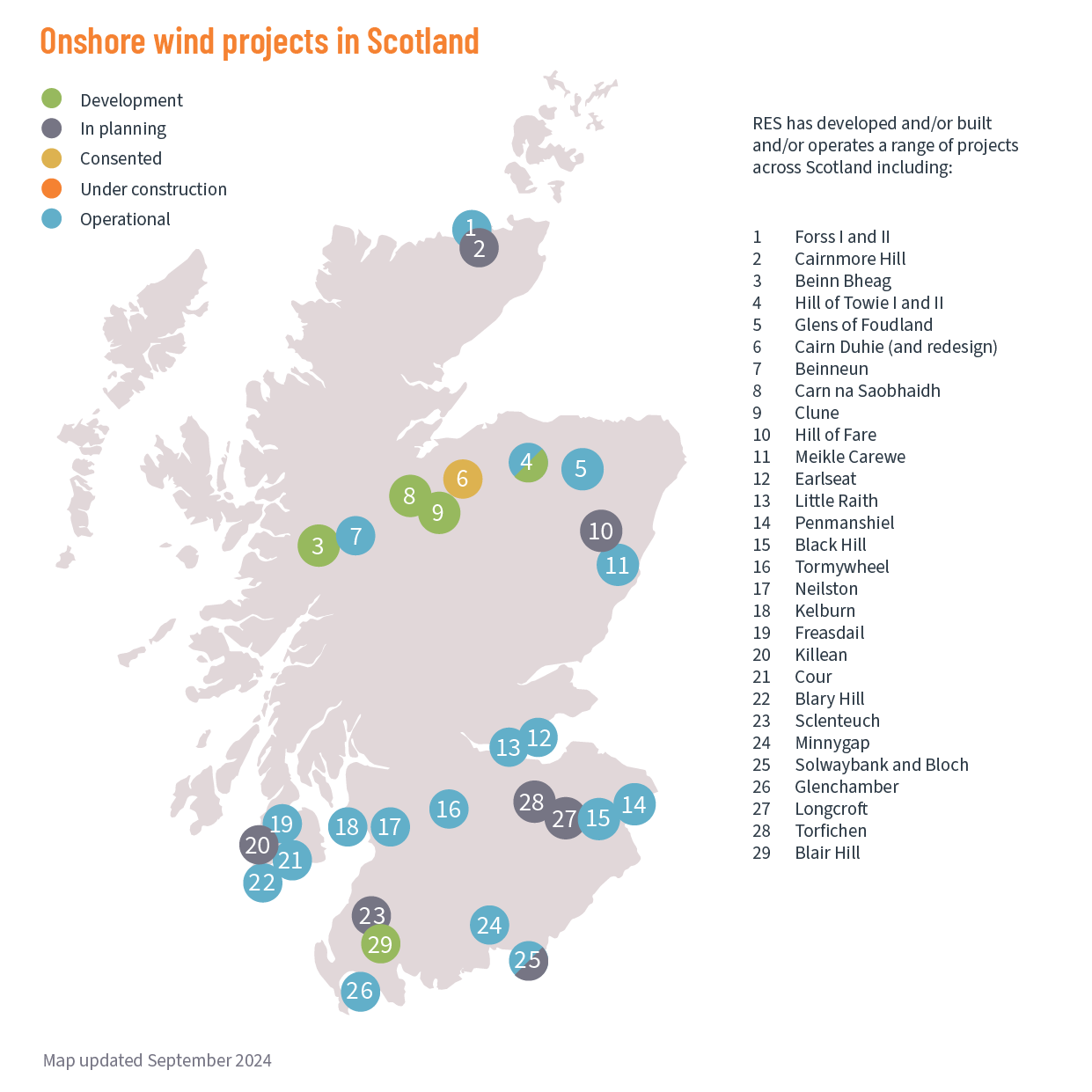

RES is a privately-owned company with a proud history in Scotland. We grew out of Sir Robert McAlpine, a British family-owned firm with over 140 years of experience in construction and engineering, including the Glenfinnan Viaduct in the Highlands and, more recently, the Sir Chris Hoy Velodrome in Glasgow. We have been developing, constructing and operating wind farms in Scotland from our Glasgow office since 1993 and to date, we have developed and/or built 22 wind farms in Scotland, with a total generation capacity of 660MW and currently operate over 550MW of wind farms across the country.

At the forefront of the industry for over 40 years, RES has delivered more than 28GW of renewable energy projects across the globe and supports an operational asset portfolio exceeding 43GW worldwide for a large client base. RES employs more than 4,500 people and is active in 24 countries working across wind, solar, energy storage, green hydrogen, transmission and distribution.

Click here to read our company overview and learn more about RES at www.res-group.com

PROJECT SPOTLIGHT

Some of our Scottish projects which are currently going through the planning phase include:

Blair Hill Wind Farm

Dumfries and Galloway

www.blairhill-windfarm.co.uk

Bloch Wind Farm

Dumfries and Galloway

www.bloch-windfarm.co.uk

Cairnmore Hill Wind Farm

The Highlands

www.cairnmorehill-windfarm.co.uk

Clune Wind Farm

The Highlands

www.clune-windfarm.co.uk

Hill of Fare Wind Farm

Aberdeenshire

www.hilloffare-windfarm.co.uk

Killean Wind Farm

Kintyre, Argyll and Bute

www.killean-windfarm.co.uk

Longcroft Wind Farm

Scottish Borders

www.longcroft-windfarm.co.uk

Torfichen Wind Farm

Midlothian

www.torfichen-windfarm.co.uk

Sclenteuch Wind Farm

Ayrshire

www.sclenteuch-windfarm.co.uk

A POWER FOR GOOD

RES seeks to be a power for good in communities that host our projects by working openly and constructively to ensure tangible local benefits. We engage early and directly with the local communities to understand how our project could support the local area and help to secure long-term economic, social and environmental benefits. This approach helps to deliver a tailored community benefits package that is aligned with the priorities of the local community and could, for instance, provide funding for projects that sit outside the parameters of a traditional application-based fund.

ELECTRICITY DISCOUNTS

For instance, RES’ unique Local Electricity Discount Scheme (LEDS) offers an annual discount to the electricity bills of those properties closest to a participating wind/solar farm in Great Britain and Northern Ireland.

Learn more at leds.res-group.com

We believe that our projects should provide direct, lasting benefits to local communities and there are a number of ways that this can be achieved.

Some recent examples of how community benefits have been delivered at some of the operational wind farms RES manage are shown below:

COMMUNITY FUND HIGHLIGHTS

Penmanshiel Wind Farm Community Benefit Fund (Scottish Borders)

- contributed £35k to the Community Council’s refurbishment of Reston play park which had been severely delayed due to the pandemic, with match funding used for the balance.

- continued the recruitment of a village caretaker to maintain services for a further three years, and maintain a role with overwhelming support from the community.

- enabled the Cockburnspath community shop to open its doors in June 2021, which is run by volunteers and also runs a delivery service. The shop also provides a place where local suppliers, makers, and crafters can sell their products, as well as providing a focal point at the end of the Southern Upland Way, for walkers to enjoy a treat.

Glenchamber Wind Farm Community Benefit Fund (Dumfries & Galloway)

- £49,000 of funding was used to complete the purchase of the Crosherie Plantation, commonly referred to as the Jenna Morra Wood, on behalf of the community. A Community Woodland Group has been established to develop the wood as a community asset, with a long-term management plan. The wider community has been involved in deciding what should be provided in the woodland by way of structures, paths, etc.

- Over £66,000 has supported the large-scale renovation of the Kenmuir Arms Hotel in New Luce, bringing the property back to life and becoming an important community asset for both the local community and visitors to the area.

- £30,000 toward the design stage of the re-development of a local GP surgery to safeguard GP services in the Old Luce area. The intention is to redevelop the site, modernise the surgery, safeguarding services and attracting the next generation of GPs, as well as providing some community owned affordable housing on site.

WORKING WITH THE LOCAL SUPPLY CHAIN

Some of the most direct and meaningful benefits that can be delivered from a project like this are jobs and employment for local businesses and contractors, in addition to the use of local services and amenities, all of which can generate a significant amount of inward investment within the area. RES has a strong track record for working with the local supply chain around its projects.

INWARD INVESTMENT

Expenditure in the local economy during the development, construction and operation of wind farms varies from project to project due to various factors including project size, project duration, and the availability of local suppliers. In recent years, RES has seen typical spend with local stakeholders, suppliers and service providers in the region of £279,000 per wind turbine during the development, construction and first year of project operation. In some cases, it has been possible to significantly improve on this number.

Some of the services and materials required include:

- Civil engineering

- Electrical works and cabling

- Plant hire and crane hire

- Environmental surveyors

- Concrete and aggregates

- Groundworks

- Steel fixing

- Labourers

- Fencers

- Accommodation

Freasdail Wind Farm, Argyll and Bute

RES’ Freasdail Wind Farm on the Kintyre peninsular in Argyll and Bute was commissioned in March 2017. Consisting of 11 turbines, the 22.55MW project has injected £6.34 million into the Argyll and Bute economy through working closely with the local supply chain – with £4.21 million being spent with local contractors, £1.56 million on local materials, £0.36 million on local supplies and services and £0.21 million on local accommodation.

Glenchamber, Dumfries & Galloway

Glenchamber, an 11-turbine wind farm located in Dumfries and Galloway has an installed capacity of 27.5MW. In keeping with our commitment to maximise economic benefit to the local area, the civil engineering contractor chosen for Glenchamber was Luce Bay Group who are based just 8 miles from the wind farm. RES’ work with Luce Bay saw more than £8 million invested into the local economy and provided employment for 45 local people.

Solwaybank, Dumfries & Galloway

Companies in Dumfries and Galloway and Cumbria won contracts totalling more than £1.5million during the construction of Solwaybank Wind Farm, near Langholm. Companies such as Grange Quarry, Pro-Tect, Hansons and Oakbank worked on The Renewables Infrastructure Group (TRIG) owned 30MW wind farm, constructed by RES. The companies provided aggregate, security, concrete and plant hire throughout the construction period.

RES is committed to using the services of as many local businesses as possible to support and maximise the benefit of the wind farm to the local economy, with contractors bringing significant value to construction because of their knowledge of the site and technical expertise.

Maintaining good links with the local communities where wind farms are situated is of paramount importance. Local contractors have extensive knowledge of the local area and bring highly skilled staff and services to projects.

RES worked in close partnership with Jones Bros Civil Engineering UK who helped to engage several firms in the area including Pro-Tect for security and cleaning, LIP Construction for road surfacing and GT Contracting for fencing. Grange Quarry, which supplied aggregate for the construction of site tracks and hard standings, is located just three miles from the site.