Solutions

Our passionate and experienced people deliver successful clean energy projects globally.

Technologies

Driving a clean energy future through state-of-the-art renewable technologies.

See all technologiesResources

Browse our latest resources, including company updates, customer stories, industry insights, and research reports.

See all resourcesCareers

Join a collaborative team of passionate individuals who engage in meaningful, stimulating, and world-changing work.

Learn moreAbout RES

We live our mission, celebrate the people making it happen and transform the way the world produces and consumes energy.

See about usOur offices

Like our business, we’re truly global – but proudly local. Find contact and location details for every RES office.

Contact us

By Vicente Gilaberte, Senior Account Manager, Sulzer Schmid, A RES Company

When RES acquired Sulzer Schmid late last year, it wasn’t just about expanding our portfolio of digital solutions – it was about changing the way we manage wind turbine blades.

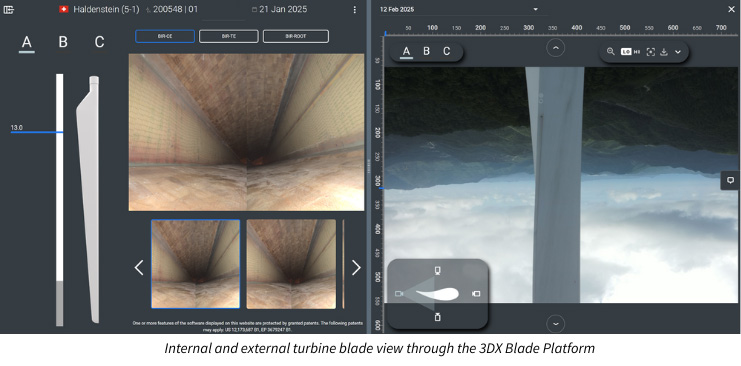

At the heart of that shift is the 3DX Blade Platform, a next-generation inspection platform that combines automated drones, AI and robotics technology to give operators a full internal and external view of blade damage in one place for the first time.

The simultaneous view of internal and external inspection data in one platform is already secured as a US patent and we’re now integrating inspection data from providers including IM FutuRe, our Spanish blade and repair specialists, who were also acquired by RES in 2023. This kind of 360-degree visibility gives asset owners an immediate edge, leading to enhanced decision-making in blade maintenance and damage repair. For example, if damage is detected on the basis of drone inspections, an internal inspection will give valuable additional insight as to whether an immediate repair is required. Being able to see both views in a single platform provides the best basis for deciding on the most appropriate follow-up actions.

But we’re only getting started.

A world of possibilities

By combining data with analytic capabilities, we aim to unlock new synergies, efficiencies, value and insights for our customers.

In the future, new capabilities will include further improvements to damage identification and categorisation, tracking how damages evolve between inspections and providing insights on the effectiveness of different repair techniques. Advancing towards predictive analytics, we’ll also be able to assess the priority of repairs and maintenance as well as identify the potential for critical failures – that means fewer surprises and less downtime.

It also opens the door to fleet-wide insights. If a specific type of damage keeps turning up on one blade model, or in one part of the world, that’s not just a repair issue – it’s a design, manufacturing, and investment conversation.

And as these insights grow, so too does our ability to act on them. Through RES’ combined expertise and acquisitions, including leading blade specialists like Bladena, we now offer full end-to-end blade care, from technical due diligence and procurement advice, to condition monitoring, inspections, root cause analysis and preventive retrofits. We also deliver repair execution, install optimisation upgrades, and apply software optimisation to extend blade life and improve performance across entire fleets.

Eventually, the platform will evolve to become fully integrated, combining both inspections and maintenance in one place. This will facilitate blade repair management within the platform and real-time updates received on work orders.

Uncovering industrywide trends

The data can also uncover wider damage trends and insights that will inform all business functions from innovation and design to operation and repair. Because the data is fully digitalised, it can be interrogated in countless ways – by location, manufacturer, blade edge, or position of the damage – and retained for analysis months or even years later.

For example, through the 3DX Blade Platform, we can track the depth of erosion and increasingly will be able to predict how the damage will progress depending on the location of the asset. The potential for this advancement was recently explored by the Netherlands Organisation for Applied Scientific Research.

It found that the protective blade coatings on blades located in the northeastern part of the North Sea have about a 20 per cent shorter lifetime than in the southwestern part. From our own data we know that blades located in Southeast Asia tend to suffer from more extensive leading-edge erosion than elsewhere in the world.

The vision: Many millions in savings

These types of insights will have significant implications across the blade lifecycle, offering the potential to save the wind energy sector millions of dollars a year.

As a fully integrated end-to-end blade management platform, 3DX already provides extensive blade management capabilities. And we really are just getting started.

As 3DX continues to evolve, so too will the value it delivers – driving smarter decisions, sharper insights and a more resilient wind industry. With leading blade experts like Bladena now part of the RES family, we’re further strengthening our support across the entire blade value chain, from technical due diligence and root cause analysis to inspection, repair strategy and lifetime extension.

Contact us to find out more about how we can help you.